During the Glasstec we were happy to announce the development of the Blank side Temperature Control system (BTC). The BTC will assist the container glass manufacturers to improve their product quality and increases the glass forming process capabilities by monitoring and controlling the temperature of the blank mould, neck ring, plunger, gob and parison at all cavities.

With this information it will be possible to easily find and maintain the optimal temperature and to retrieve optimal temperature after equipment and/or job change. As the IGC and the Gob Assist, the BTC is an add on to an infrared camera system and as such forms an integrated system with the infrared camera system.

The BTC consists of a sensor module that glides along a rail system, which is the same rail system as used for the Gob Assist. Like the Gob Assist, the BTC is also a contactless system.

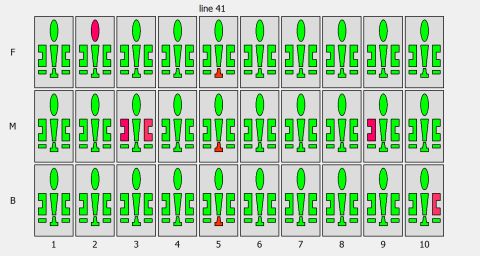

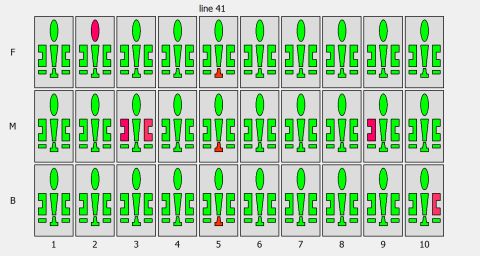

At the hot end the IR-D system detects the intensity and asymmetry of infrared radiation emitted by the hot glass containers. The pre-conditional IR-D measures the variation of intensity and asymmetry of all glass containers over time, as well as the glass distribution. A change in intensity distribution at a certain cavity is an indication for a change in temperature distribution at the blank side. Through an intuitive user interface, the optimal temperature distribution for this cavity can be obtained.

Connected to the company’s network the BTC enables remote access for production specialists to review the status of the forming process and apply changes to settings and configurations.

Currently the BTC is still in development. It is expected to finish the development and testing beginning 2011, after which the product will be commercially available.