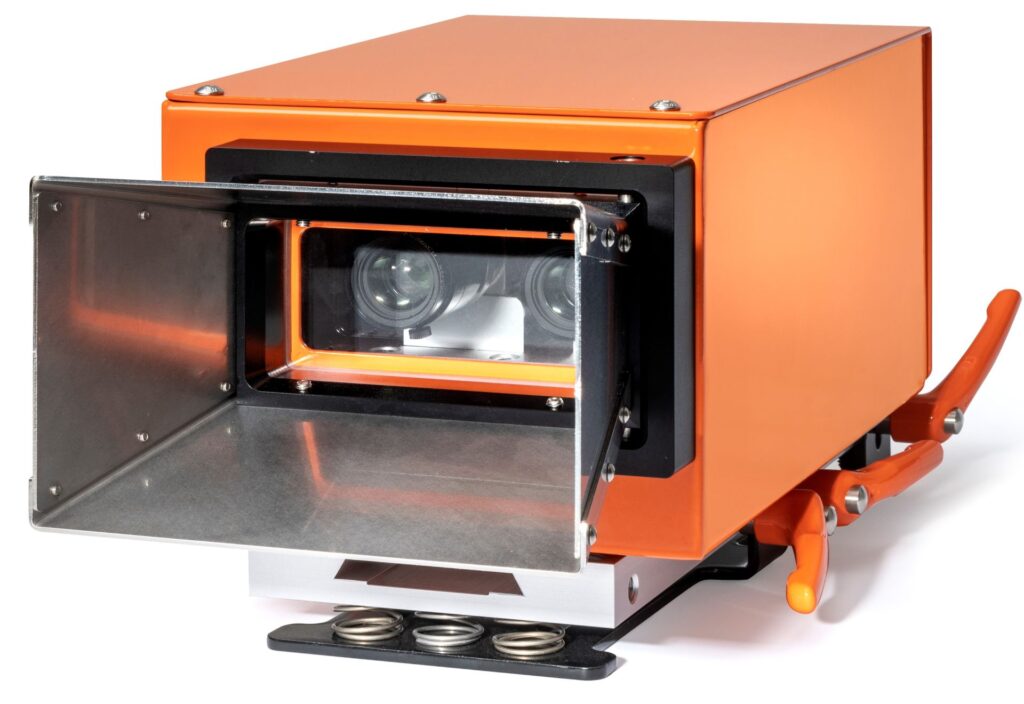

BlankRobot

Smarter, Safer, More Efficient Swabbing The BlankRobot is revolutionizing swabbing technology in glass production. By eliminating manual swabbing and extending swabbing intervals, it reduces process variation and maximizes output. With its fully automated operation, the BlankRobot is an essential solution for every glass factory and …