The GobAssist-BTC assists container glass and tableware manufacturers to improve their product quality and increases the glass forming process capabilities by monitoring and controlling the gob loading combined with temperature measurements of the blank mould, neck ring, plunger and parison for each individual cavity.

operating principle

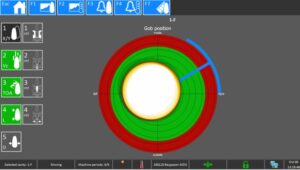

The GobAssist unit observes the gob trajectory after the gob exiting the deflector until it enters into the blank mould. With two high speed camera gob speed, length, time-of-arrival, loading position and gob shape are measured. Moving the camera unit continuously from section to section these measurements are repeated every 15-20 minutes.

The GobAssist unit observes the gob trajectory after the gob exiting the deflector until it enters into the blank mould. With two high speed camera gob speed, length, time-of-arrival, loading position and gob shape are measured. Moving the camera unit continuously from section to section these measurements are repeated every 15-20 minutes.

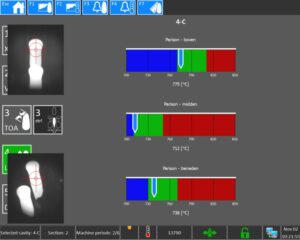

In the same unit the BTC (Blankside Temperature Control) measures temperatures of mould materials and – uniquely – of glass as well. Of each cavity it measures one or more positions on the blank mould, neck ring, plunger and parison.

A simple user interface allows for real time corrective action. At the same time the effect on the glass distribution of the product is visualized by IR-D system.

The GobAssist-BTC ensures to find, to maintain and to retrieve the optimal loading and temperature distribution within seconds, eliminating two most important sources of process variation and minimizing critical defects related to bad loading or bad temperature distribution.

open data interface

XPAR Vision enables open data connections to standard and proprietary Production Information Systems to present and correlate real time hot end information in combination with other production data from furnace, feeder, Cold End inspection and laboratory systems. Uniquely the XPAR Vision GobAssist-BTC is integrated with major IS-machine timing systems to enable closed loop interfaces for automatic Mould Cooling and Glass Distribution control.

capabilities

- Real-time cavity related data collection

- Entrance position of the gob into the blank mould

- Speed of the gob

- Time of arrival

- Gob length

- Gob shape

- Blank temperature

- Neck Ring temperature

- Plunger (NNPB) temperature

- Parison temperature

- Single, double, triple and quad gobs support

- Multi product support

- All glass colours

- Round and non-round ware

- Blow-Blow process support

- Press-Blow process support

- Wide Mouth Press & Blow process support

- NNPB process support

- IR-D integrated reject functionality of bad ware

Customer opinion

Park Cam

ParkCam – Bozüyük-Bilecik Turkey – has commissioned its new furnace equipped with four new state-of-the-art production lines. These 16 section Bottero IS-machines have been provided with the latest hot end sensor technology from XPAR Vision. Each IS-production line uses the InfraRed Dual camera system in …

Read entire storyNeed more information?

Get in touch with Paul Schreuders (CEO)

Latest shared news and knowledge articles

Digital resorting: held ware dramatically reduced!

In every container glass factory held ware and resorting is a pain in the butt, and even getting worse. With XPAR Vision’s Long Term Image Storage this held ware and resorting will be dramatically reduced. Held ware In case of any suspicion for bad quality ...

Multi-view monitoring for automatic gob weight control

Specialising in and leading innovations of advanced sensor and robot technology, XPAR Vision’s products and services help to improve the forming process performance and quality control for the global container glass and tableware industries. Paul Schreuders explains how the company’s latest sensor enhances its portfolio of solutions and offers ...

European Union, SNN and EZK SUPPORT XPAR Vision DEVELOPMENT

Thanks to the support of the European Union, SNN and the Ministry of Economic Affairs and Climate Policy (EZK) through a EFRO grant, XPAR Vision is able to develop and valorise 2 prototype sensors for glass composition and lateral glass distribution, including integration into a ...