The Gob Assist is currently operating in three different factories. The results of experiments are very good, and the potential benefits promise to be enormous. Besides these direct operational benefits, the Gob Assist gives good insight in the loading process itself, and how to optimize it.

Through the experiments we have learned for example:

- what type of scoop, trough and deflector to use

- how to align the scoop, trough and deflector

- that different coatings have different results regarding loading

- how to extent the life time of blank moulds

- how to influence the temperature of the deflector in order to get an optimized loading

Insight in the loading process itself and how to optimize it, brings new operational benefits within reach.

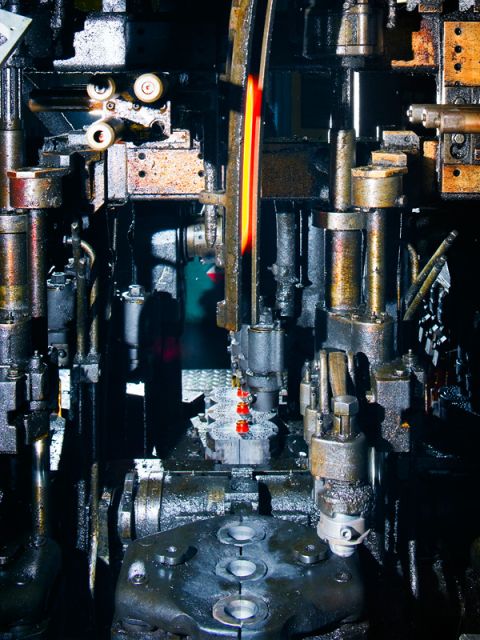

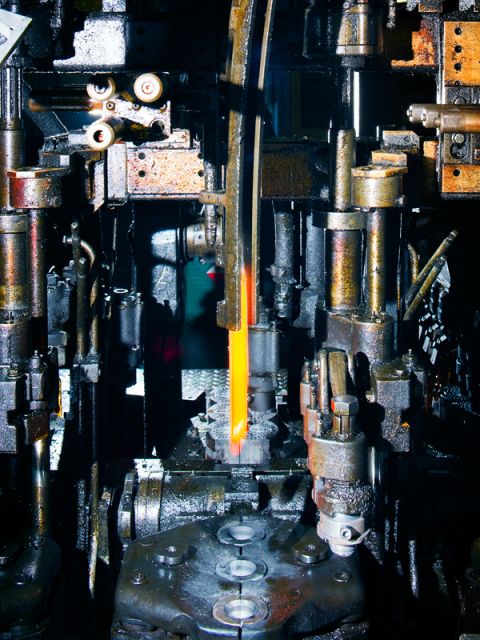

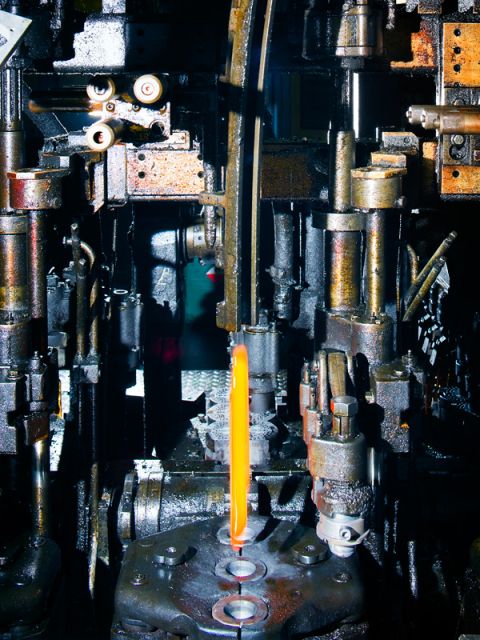

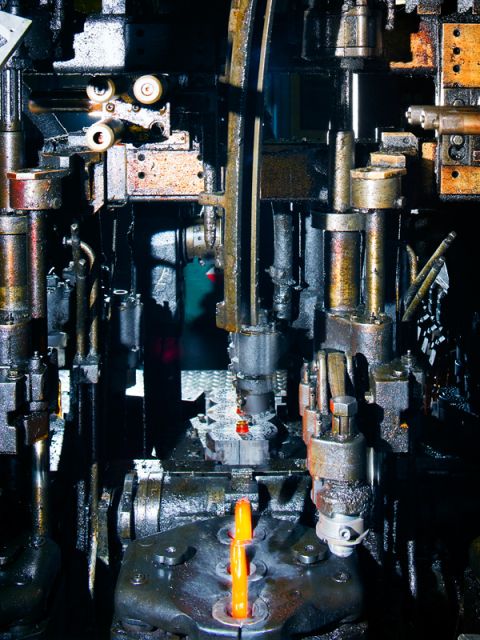

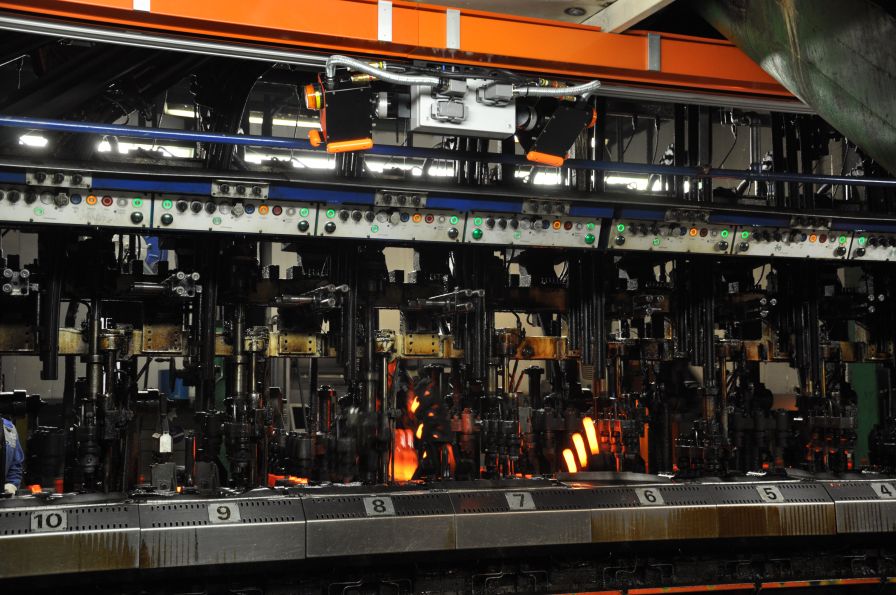

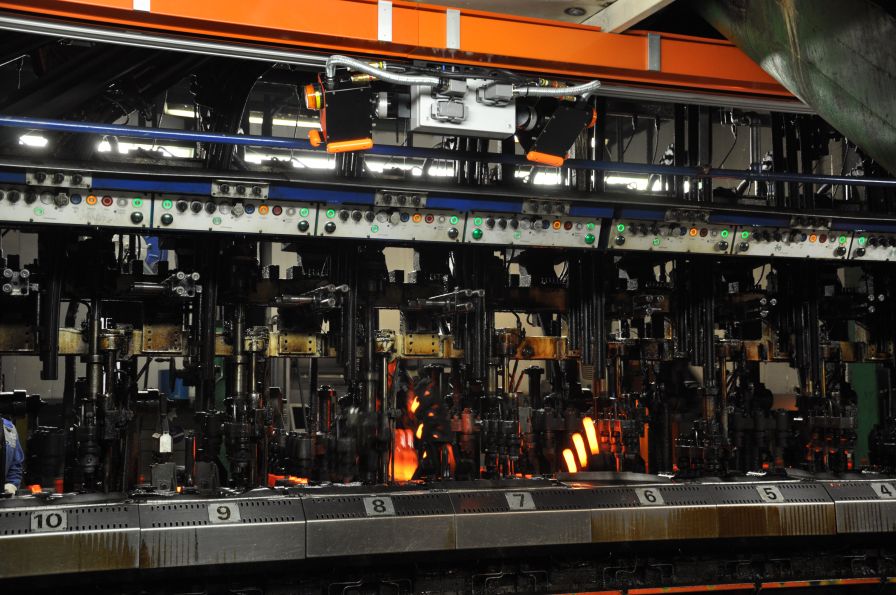

With the Gob Assist we are able to monitor and measure the speed, length, position, shape, orientation and time of arrival of the gobs falling into the blank moulds. With this information it is possible to easily find and maintain the optimal gob loading and to retrieve the optimal gob loading after equipment change and/or job change. The operational benefits are obvious: higher efficiencies and less (aspect) defects, improved glass distribution en less process variation.

Currently we are finalizing the development of this Gob Assist. Main challenges are physical fit on the IS machine and optimizing the hardware configuration accordingly. Within a few months from now we will have the first commercial versions in operation.