Handling of customer complaints, recalls, resorting and claims is more than a headache for many glass container producers. Above all, when these things occur, time and money spending is high.

Based on several customer request, in recent months XPAR Vision has finalized the development of so-called Long Term Image Storage (LTIS). The LTIS is marketed as an add on to XPAR Vision’s InfraRed Dual camera system (IR-D) for inspection of all glass containers produced and monitoring the glass forming process. Where in standard IR-D a maximum of 100.000 images of only rejected bottles are stored, with this LTIS feature, images from all containers passing the IR-D are stored, effectively 2 images per unit.

Millions of images

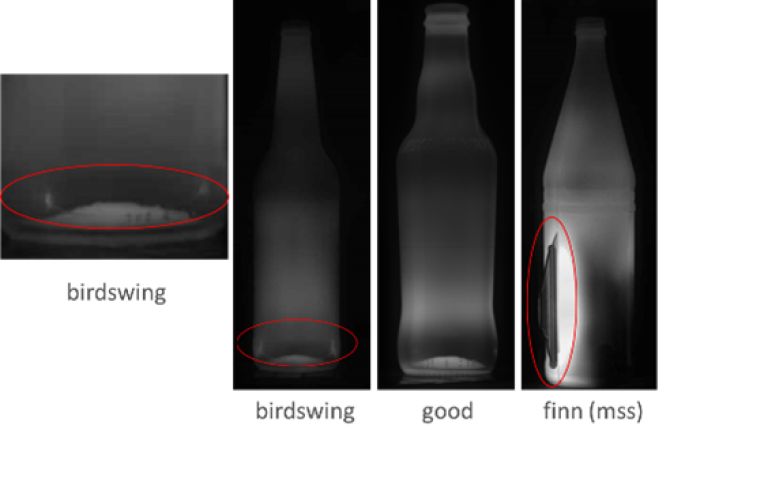

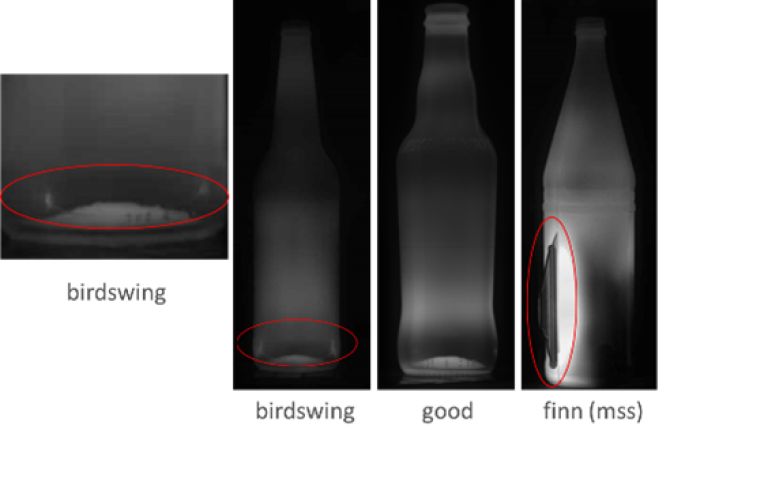

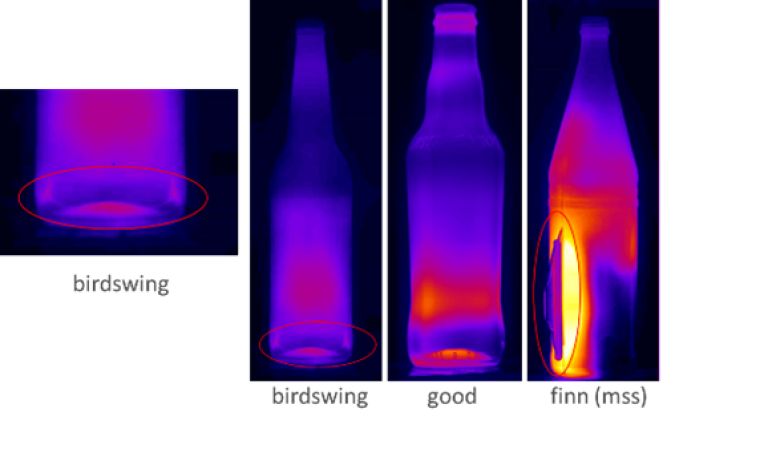

Upon the choice of the customer storage can be organized on local hard disks or in the Cloud, for as long as the customer wants: up to 12 months and more. Through the technology chosen literally a “unlimited” number of images can be stored. Logically with the help of an XPAR viewer the stored images are easy to retrieve. Images are presented in a grey scale or color.

Great value

From first customers’ feedback, the main value of using LTIS are:

- Track and trace: support internal or external traceability on shorter and longer term. In case of internal use the availability of all images including their time stamps allow for accurately determining the minimum of held ware, as such dramatically reducing the numbers of units to resort. In case of external recalls the same availability of all images allows to identify the contaminated pallets precisely with proof towards the customer and so potential damage can be managed and limited.

- Improve Hot End settings and alignment of Hot End and Cold End settings, as such improving on (internal) quality control and on (external) quality to customer.

For further detailed information about this new add-on please contact your XPAR Vision Account Manager or drop an email to sales@xparvision.com.