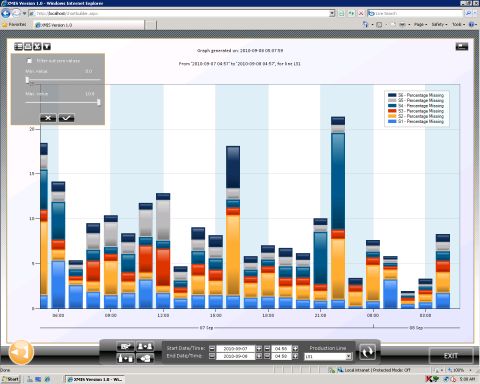

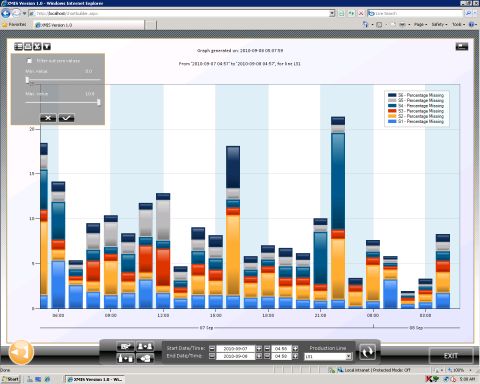

Once our hot end solutions (IR-D, IGC, Gob Assist and BTC) are implemented at the production line they gather enormous amounts of information about the forming process which is presented to the user. Without XMIS installed in the plant this information would be stored for a short duration before being discarded and therefore lost for further analysis and future reference.

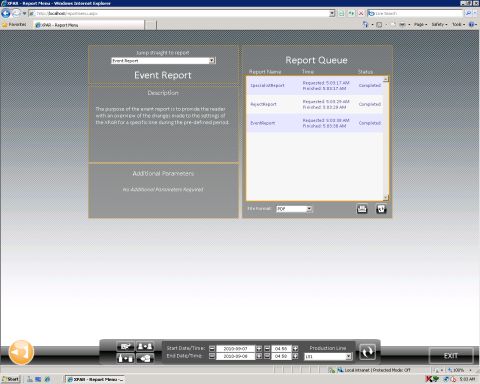

XMIS enables the user to analyze for critical defects, perform process improvements and do benchmarking between i.e. lines, sections and cavities. It also provides access to historical data, for traceability in case of customer reclamations. On top of this XMIS includes a mail service which can deliver standardized hot end reports on a daily basis. Furthermore XMIS has an export function to Excel, CSV and XML format, and also the possibility to interface with systems like SIL and APS.

This makes XMIS an invaluable tool to better understand the production process and improve on both process and product quality.

XMIS allows all process data to be stored on a centralized server for longer periods of time. It provides a web based user interface to retrieve this data in a intuitive way by generating user defined graphs and dashboards and pre-defined reports and queries.