Need more information?

Get in touch with Paul Schreuders (CEO)

- +31503162888

- schreuders@xparvision.com

According to Paul Schreuders, GobAssist from XPAR Vision makes the secret world of gob loading visible and understandable. It reveals the state of loading and at the same time gives the correct information at the right time to avoid performance and product quality problems.

With every glassmaker aiming to make bottles correctly first time, providing the highest performance against the quality expectations of the customer, many threads and disturbances are fought against hour by hour at the hot end. Stability and control are the sacred terms about which all glassmakers dream. Arguably the most important process step in making good bottles and jars is the loading of gobs into the blanks. Its importance reflects on the quality of bottle or jar, as well as IS machine performance and the output of the production line in terms of packed product.

To gain control of gob loading, it is necessary to have access to continuous information of all critical aspects of the loading process. Latterly, glassmakers have used hand-held tools to measure gob speed, as well as its temperature in some cases. On a daily basis, these tools fail to provide complete information relating to loading. It is only cavity-related but the most important features like shape, time of arrival and position of the gob in the blank is missing. Considering this lack of information from factual measurements that is collected continuously and in a comparable way (at the same time, at the same position) on the most important process step in glass forming, XPAR Vision has introduced its GobAssist equipment to the glass container industry. Subsequently, a number of respected glassmakers have gained operational experience with this equipment. Based on this experience, it can be concluded that GobAssist provides substantial benefits to process performance and the quality of containers. Although gobs after the cut seem to be mostly in good order, however, what is the shape of the gob when it enters the blank mould?

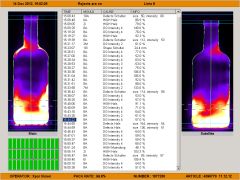

More often than not, huge variations in gob shape occur; over time, gobs can become shorter because of increased friction in the deflector (see figure 1). Consequently, the speed of the gob is lower, resulting in later arrival at the blank (figure 2). Logically, the gob’s diameter increases when its length shortens. If remedial action is not taken at the correct time, the gob fails to load fully into the blank, causing section stop (figure 3).

The effect on the quality of bottle is obvious, which is immediately shown by the IR-D system, rejecting bottles with ‘stuck bottom’ defects (figure 4). GobAssist will give an alarm, as shown in figures 5a and 5b.

After remedial action (swabbing the deflector) loading is good again, as shown in figure 6. Separately, the example given in figure 7 was provided by a different glass industry user, showing that a birdswing was detected due to poor loading. Clearly, this example shows that measuring once a day is inadequate to keep loading under control. The time between a ‘good’ gob and a ‘bad’ gob that can be the cause of many section stops and critical defects can be as little as 15 minutes. Only with the assistance of an accurate automatic measuring system like the GobAssist can a stable process be achieved.

Customers using GobAssist conclusively confirm a significant reduction of section stops and are able to prevent the production of such critical defects as stuck bottoms, thin spots, leaners and birdswings. In addition to the benefits of improved performance and product quality, prospective users can imagine the impact on stand time for blanks, the life expectancy of moulds, maintenance on moulds and IS machines, reduced workload for operators, workers’ safety, less resorting, fewer customer reclamations, reduced energy consumption, less carbon emission etc. GobAssist also answers customer demands for greater flexibility as job changes can be managed more efficiently when gob loading is under control. In addition, better control of gob loading opens the way for (ultra) lightweighting and production speed increases.