Need more information?

Get in touch with Paul Schreuders (CEO)

- +31503162888

- schreuders@xparvision.com

XPAR Vision is a firm believer that the current performance of the glass container industry has not reached its limit. Weight reduction, waste reduction and zero defects production are now possible by using the company’s equipment. In a series of exclusive articles for Glass Worldwide, Paul Schreuders shares the results of implementing the company’s technologies and how they help the glass industry.

In part one of this series, XPAR Vision and its hot end sensor technology solutions were explained briefly. It was stated that the glass forming process is complex and dependent on many, mostly unknown or misunderstood parameters. Also the glass forming process is mainly steered by operator experience, which by nature depends largely on each single operator. The introduction of hot end sensor technology solutions like the InfraRed Dual camera, the InfarRed Gob weight Control, the GobAssist and the Blank side Temperature Control are necessary steps towards steering the forming process by science instead of by experience. By having systems available, cause and effect relations are easy to analyse; if a gob parameter changes (measured by the GA), it inflicts the loading process, affecting the parison condition (measured by BTC) and the result is a different glass distribution in the bottle or jar, indicated by the IR-D. Conversely, the root cause of any distortion in bottle quality or process stability identified by the IR-D can easily be analysed by the information provided by GA and/or BTC. Collectively, this information will lead to insight of the forming process and knowledge leads to sustainable solutions.

Parts two to five of the ‘Amazing discoveries…’ series of articles focused on the GobAssist (GA), which monitors essential loading parameters, including:

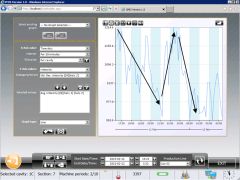

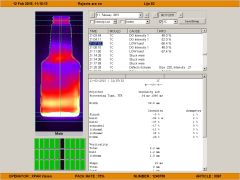

The GA (figure 1) is mounted on a rail system and measures these loading parameters sequentially, section by section. Two high speed cameras capture the trajectory of the gob falling from the deflector into the blank mould. The GA software analyses the many images and gives detailed information about the loading process.

Throughout the second, third and fourth articles, it has been explained how loading of the gob and specifically, different loading parameters like gob speed, gob length, gob position and gob time of arrival, influence the forming process in terms of efficiency and quality. It was demonstrated clearly how bad loading affects glass distribution, defects, cavity jams and sections stops. Also considerable insight has been built up on how these loading parameters in itself are influenced (and can be influenced!) b, for example, friction in trough or deflector, poor alignment of gob distributor, condition of the shear block where the gobs are cut and the state and quality of the coating used. As a result, insight has been gained on how to maintain and retrieve the different loading variables within the respective boundaries, in order to produce the best bottles with the highest efficiency repetitively. Throughout, the GA has been proven to measure automatically, accurately and consistently and to be a valuable device that is simple, easy and safe to use.

In article five, it was explained how exactly loading influences glass thickness. Understanding the relationship between the specific loading variables and glass distribution (glass thickness) and use that logic to control glass thickness is of utmost importance on the way to drastically reduce the weight of bottles produced. And everybody in glass will understand the significant side-effect of this: The opportunity to increase speed, which turns out to be the main profit contributor.

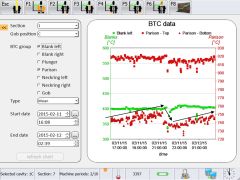

Mounted on the same rail as the GA, the Blank side Temperature Control (BTC) system (figure 1) is capable of measuring the temperature of the essential parts at the blank side:

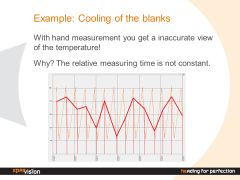

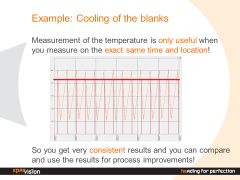

The BTC always measures the temperature on the same position and at the same time, giving reliable and precise results. Realising that the plunger cools down by more than 100°C in one tenth of a second, manual measurements can never be this accurate! The BTC is fast, with multiple measurements in different cavities of a section taken within one cycle. Two special sensors, one for the temperature of metal and the other for the glass temperature, contribute to the effectiveness and extreme accuracy of the BTC (figure 2).

Knowing that glassmaking is a process of heat exchange and cooling, the importance of temperature measurement is well accepted throughout the industry. Nevertheless, the applications of temperature measurements in the context of all other variables in the forming process are very different and the general understanding still low. For example, how does loading influence the temperatures measured and are actions taken on solely temperature measurements the correct ones? As a leader in the area of hot end sensor technology development, XPAR Vision sees it as its responsibility to improve general understanding in this field.

Experiments have been conducted relating loading to parison temperature. In conclusion, parison temperature is influenced by loading. Knowing that, a control mechanism on parison temperature alone (while not controlling loading) might lead to an improvement in comparison to the situation of having no control mechanism but will never lead to an optimised forming process.

Figure 3 visualises how gob length change leads to parison temperature change, which leads to thin necks and/or blisters. Not knowing or not admitting the relationship between gob length and parison temperature might easily lead to the wrong and thus ineffective steering action.

In future articles, the focus will turn to amazing discoveries emanating from field work with different hot end sensor technology solutions, including the Blank side Temperature Control solution.