Smarter Inspection. Superior Quality.

IR SmartVision is a breakthrough system for Hot End inspection and process monitoring for glass container manufacturers. It combines intelligent defect detection, real-time process insights, and user-friendly operation to help you deliver consistent quality, reduce waste, and optimize production. Whatever type of container glass you produce including non-round and those with engravings/ embossings, IR SmartVision ensures every container meets your highest standards with minimal setup and maximum reliability.

Operating Principle

IR SmartVision uses infrared imaging from three sides to achieve a full 360° container inspection. Advanced algorithms analyze the images and turn data into clear insights:

- SmartDetection

Self-learning defect detection that adapts to any shape, color, or embossments and engravings, with profiles in minutes. - SmartAdvices

SmartAdvices Real-time process feedback using statistical control to prevent rejects and forming issues. - SmartScreen

SmartScreen Web-based touchscreen with customizable widgets for instant insights and simple setup.

Capabilities

SmartDetection

SmartDetection is a self-learning defect detection algorithm with minimum set up that builds a profile of what a normal container looks like without needing pre-labeled training data or personnel assistance. It uses infrared intensity to learn product-specific features on the fly and flags deviations in real time.

Key Features

- Complete inspection of round and non-round containers

- Works with all glass colors and embossed surfaces

- Minimal impact from container orientation

SmartAdvices

SmartAdvices transforms complex infrared data into actionable insights. The system monitors the forming process in real time and alerts operators to issues like gob loading problems or excessive rejections. Operators can explore these insights via the SmartScreen interface, helping them make informed decisions quickly.

Supported Process Insights

- Verticality (thermal & mechanical)

- Conveyor belt and ware spacing variations

- Gob weight and glass composition inconsistencies

- Excessive IS/IR rejects

- Section-specific ware spacing

- Trapped baffles, scabby bottoms, and more glass distribution change or glass wall thickness

Interested in this product?

Reach out to our sales team

SmartScreen

Intuitive touchscreen interface with actionable insights

Experience a modern, intuitive interface with crystal-clear visuals for effortless monitoring. Get instant insights into production and cavity performance, supported by SmartAdvices from process data. The new reject overview makes filtering and inspection easy and fast.

SmartView

Comprehensive defect detection with 360° coverage

SmartView supports more than two cameras, providing enhanced bottle coverage of up to 360 degrees, enabling better detection of defects such as fins, blisters, cracks, stones, thin spots, birdswing, and spikes, while also improving the monitoring of glass distribution.

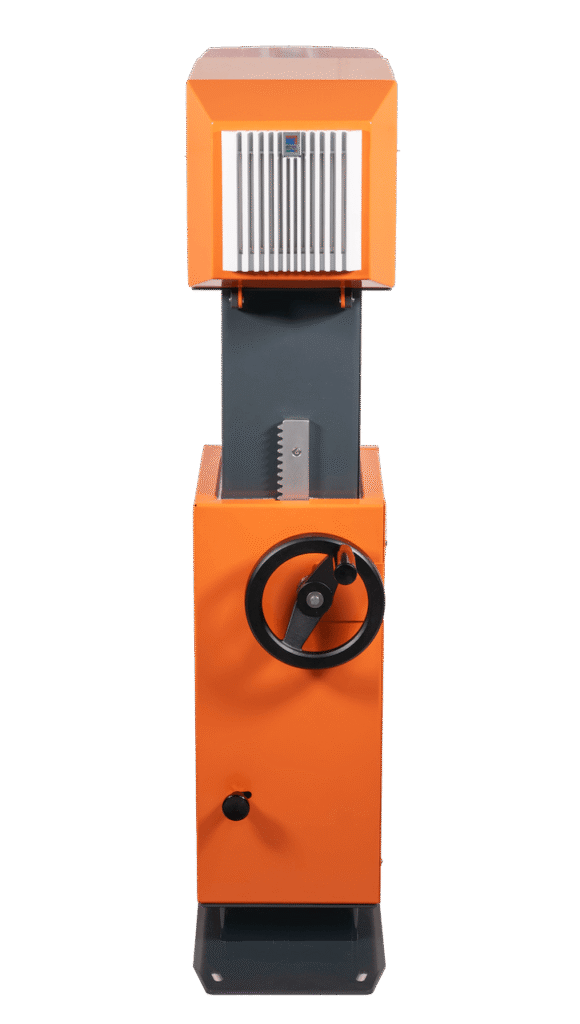

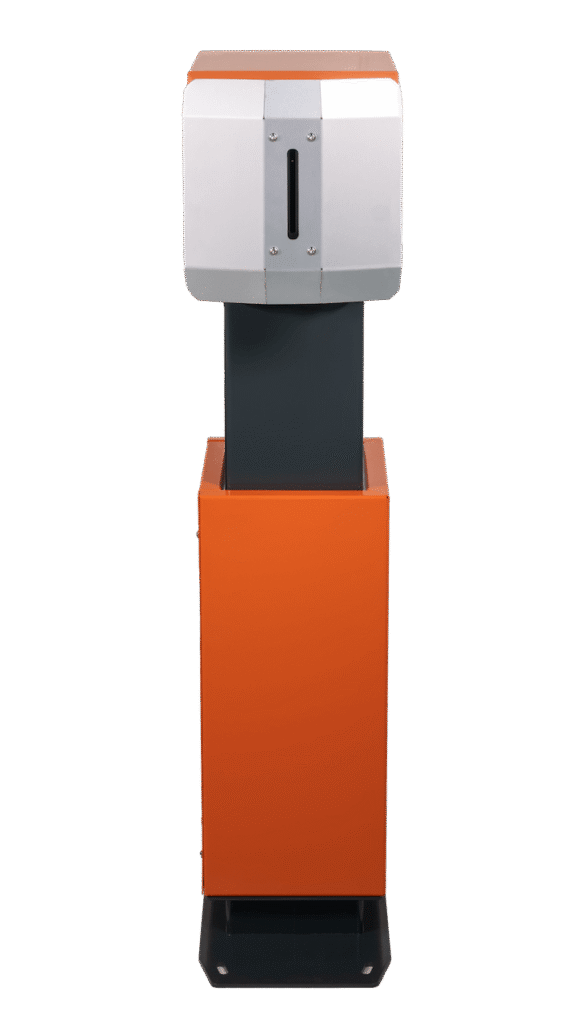

SmartCooling

Compact camera stand with thermoelectric cooling—reduces footprint and improves system stability.

- Thermoelectrically cooled (no chiller)

- Minimal to no maintenance required

- Small footprint for easy installation (230 x 500 mm)

- In height adjustable from 700 – 1200 mm

Upcoming features

SmartSettings

Quick and intuitive setup for faster deployment and less operator training. Expected to be ready by the end of 2026.

SmartClassification

Automated defect classification for faster decision-making and reduced manual inspection. Expected to be ready by the end of 2026.